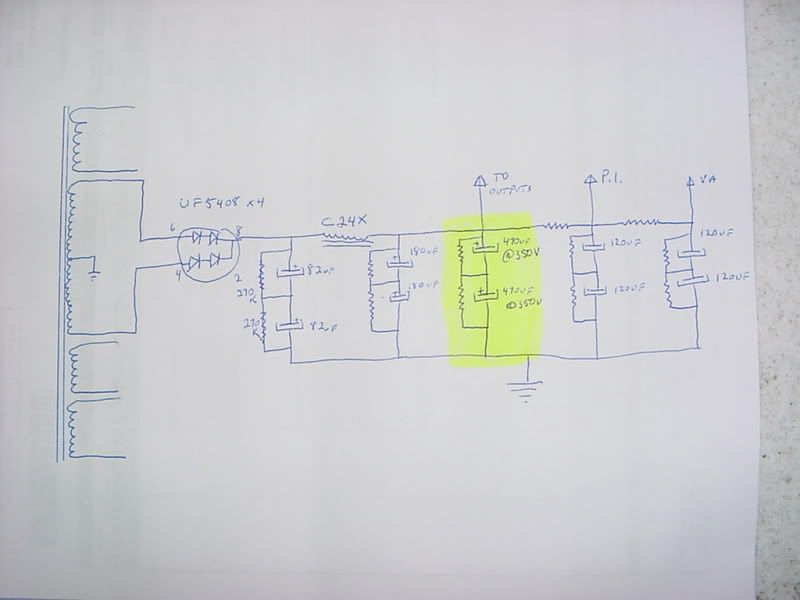

This cap was removed from another Dyna project in good physical condition. I ground off the lower lip and removed the guts, then stuffed two 470uf @ 350v Panasonic caps in series and 270k bleeders. Then reinstalled just the terminal plate and retainer ring and carefully crimped it shut. This will net a single 235uf @ 700v cap to parallel with the second caps on the cap board. Caps on the board are 2x 82uf@400v, 180uf@350v, 4x 120@350v.

The power supply ends up being 41uf@800v - choke - 325uf@700v - 6.8k - 60uf@700v - 22k - 60uf@700v. Now I can use SS diodes and not have to worry about it blowing up and also use a 5AR4 if I wish.